The Hossfeld Bender is a versatile tool for bending tube, pipe, flat stock, and more, offering precision and reliability in metalworking projects. Its universal design and comprehensive instruction manual ensure safe and effective operation, making it a valuable asset for professionals and DIY enthusiasts alike.

1.1 Overview of the Hossfeld Bender

The Hossfeld Bender is a universal bending tool designed for tube, pipe, flat stock, and other materials, offering precision and versatility. Known for its durability, it supports various die sets, enabling a wide range of bending applications. The Model No. 2 is particularly popular for its adaptability in metalworking projects. Whether for fabrication, construction, or DIY tasks, the Hossfeld Bender delivers consistent results. Its robust design and interchangeable tooling make it a reliable choice for professionals and hobbyists alike. The included instruction manual is crucial for understanding its full capabilities and ensuring safe, effective operation across different materials and bending requirements.

1.2 Importance of the Instruction Manual

The instruction manual for the Hossfeld Bender is indispensable for users to understand its capabilities, limitations, and safe operation. It provides detailed setup guides, operation steps, and maintenance tips, ensuring optimal performance. The manual also includes troubleshooting sections to address common issues, helping users resolve problems efficiently. By following the manual, users can maximize the bender’s potential while maintaining safety standards. It serves as a comprehensive resource for both novice and experienced operators, making it essential for achieving precise and consistent bends in various metalworking applications. The manual’s clear instructions ensure proper usage, preventing damage to the machine and material. It is a vital companion for anyone working with the Hossfeld Bender.

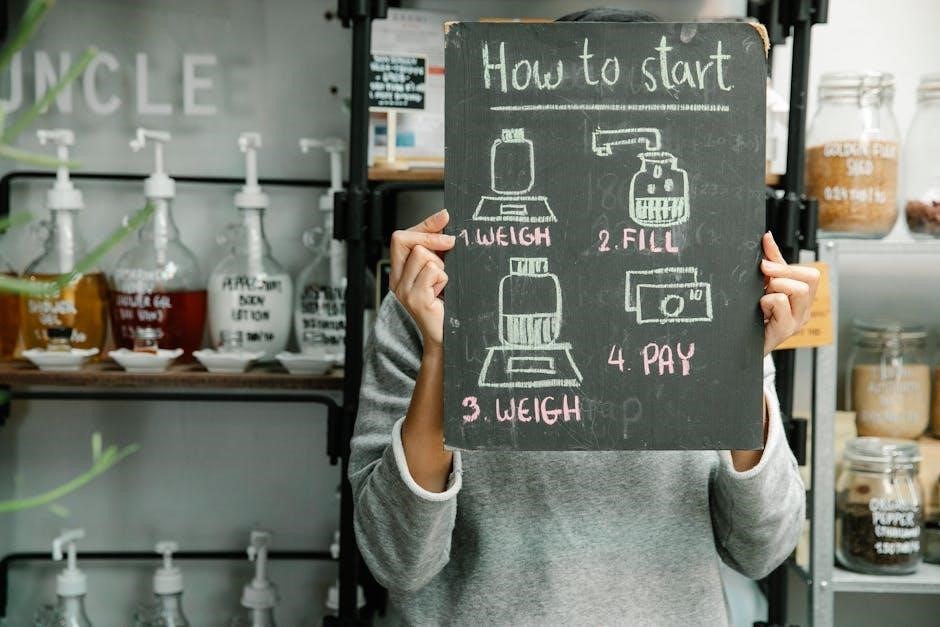

Setting Up the Hossfeld Bender

Setting up the Hossfeld Bender involves mounting the unit, aligning components, and securing it with bolts. The process is quick and straightforward, as detailed in the manual.

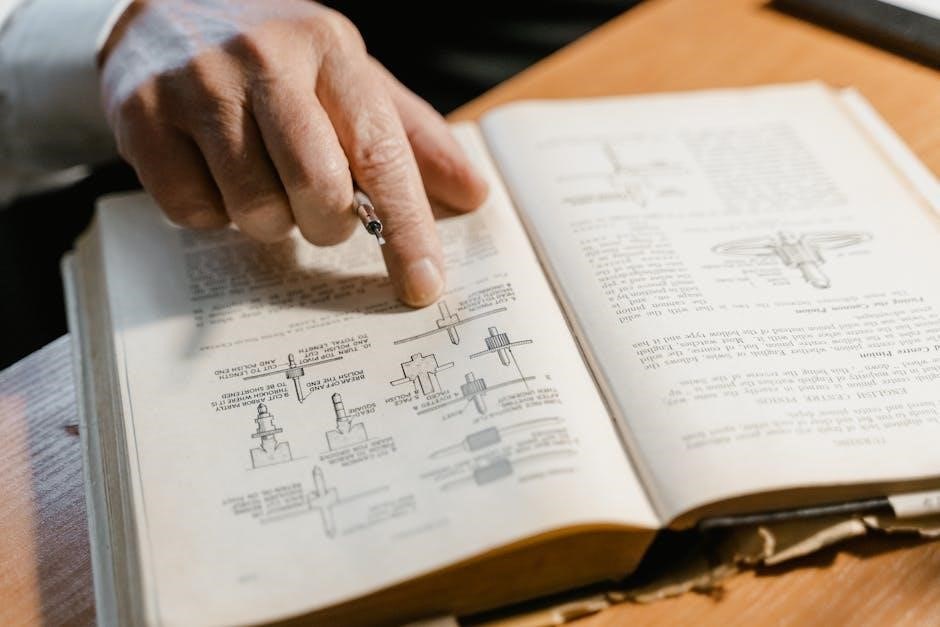

2.1 Hydraulic Hardware Setup

The hydraulic hardware setup for the Hossfeld Bender is essential for optimal performance. According to the manual, the hydraulic attachment can be installed quickly using four bolts. This setup enhances bending precision and power, making it ideal for heavy-duty tasks. The system is compatible with any Model No. 2 Hossfeld Universal Bender, ensuring versatility for various projects. Proper installation requires following the illustrated instructions provided, which guide users through each step. Once set up, the hydraulic system allows for smooth, consistent bends, making it a crucial component for achieving professional-grade results in metalworking applications.

2.2 Installing the Bender

Installing the Hossfeld Bender requires careful preparation and adherence to the manual’s instructions. Begin by preparing the installation site, ensuring it is clean and free from obstructions. Unpack the bender and inspect for any damage or missing parts. Mount the bender to a sturdy workbench or standalone base using the provided hardware, ensuring stability. Level the machine to guarantee precise operation. Connect the hydraulic system, following the steps outlined in the manual. Once installed, test the bender with a small project to ensure proper function. Proper installation is critical for achieving accurate bends and prolonging the machine’s lifespan.

Operating the Hossfeld Bender

Operating the Hossfeld Bender involves mastering basic bending techniques, utilizing appropriate die sets, and ensuring safety protocols are followed. The instruction manual guides users through various bending methods, including flat stock handling and creating precise angles, while emphasizing proper machine setup and maintenance for optimal performance and longevity.

3.1 Basic Bending Techniques

Mastering basic bending techniques with the Hossfeld Bender is essential for achieving precise results. Start by ensuring the machine is properly set up and the correct die set is installed. For tube and pipe bending, align the material with the die’s centerline and slowly apply hydraulic pressure. Flat stock bending requires securing the material firmly and using the radius block for consistent curves. Always follow the instruction manual’s guidelines for material compatibility and bending limits. Practice with smaller projects to build confidence and refine your skills. Regularly refer to the manual for troubleshooting common issues and optimizing your bending process.

3.2 Bending 180 Degree Angles

Bending 180-degree angles with the Hossfeld Bender requires precise setup and technique. Begin by selecting the appropriate die set designed for wrap-around bending. Install the L-type swinging frame, as specified in the manual, to facilitate tight radius bends. Align the material with the die’s centerline and secure it firmly. Apply steady hydraulic pressure, ensuring the bend progresses smoothly. For consistency, use the included radius block to maintain uniformity. Always refer to the manual for specific die recommendations and material compatibility. Practice on scrap material to refine your technique and achieve flawless 180-degree bends. Regular maintenance and proper tooling alignment are crucial for repeatable results.

3.3 Using Different Die Sets

Using different die sets with the Hossfeld Bender enhances its versatility for various bending tasks. Die sets are specifically designed for tube, pipe, flat stock, and angle iron, ensuring precise bends. Always match the die set to the material type and desired radius. The manual provides detailed guidelines for die selection and installation. Proper alignment is crucial; misaligned dies can damage the material or the tool. Lubricate dies periodically to maintain smooth operation. For complex bends, consider using interchangeable dies or specialized tooling. Refer to the Hossfeld catalog for compatible options. Regularly inspect dies for wear and replace them as needed to maintain bending accuracy and prevent damage to the equipment.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance. Lubricate moving parts, check hydraulic fluid levels, and inspect for wear. Troubleshooting common issues like misalignment or die damage prevents costly repairs and downtime.

4.1 Routine Maintenance

Regular maintenance is crucial for the longevity and efficiency of the Hossfeld Bender. Begin by lubricating all moving parts to prevent friction and wear. Check the hydraulic fluid levels and top them off as needed to ensure smooth operation. Inspect the dies and tooling for any signs of damage or wear, replacing them promptly if necessary. Clean the machine thoroughly, removing any debris or metal shavings that could interfere with its performance. Additionally, review the instruction manual for specific maintenance schedules and recommendations tailored to your model. A well-maintained Hossfeld Bender will deliver consistent results and reduce the risk of unexpected downtime.

4.2 Common Issues and Solutions

Common issues with the Hossfeld Bender often relate to improper setup or maintenance. Alignment problems can occur if the dies are not properly secured, leading to uneven bends. To resolve this, ensure the die sets are correctly aligned and tightened according to the manual. Damaged or worn-out dies can also cause inaccurate bends; replace them with genuine Hossfeld parts. Hydraulic leaks may develop over time; inspect connections and seals, replacing them if necessary. If the bender fails to hold pressure, check the hydraulic fluid level and pump for any blockages. Refer to the troubleshooting guide in the manual for detailed solutions and preventive measures.

Advanced Features and Capabilities

The Hossfeld Bender excels in bending flat stock, creating square bends, and handling various materials like tube, pipe, and angle iron with precision and ease.

5.1 Bending Flat Stock

Bending flat stock with the Hossfeld Bender offers precision and control, enabling the creation of complex shapes. The machine’s design accommodates various materials, ensuring clean, accurate bends. By following the manual’s guidelines, users can achieve consistent results across different projects, making it ideal for both intricate and straightforward applications.

5.2 Creating Square Bends

Creating square bends with the Hossfeld Bender is a precise process that requires the use of specific dies and tooling setups. The flat-face radius block is essential for achieving sharp, 90-degree angles. By following the manual’s instructions, users can ensure accurate alignment and consistent results. Proper setup and die selection are crucial to avoid deformation and maintain the integrity of the material. The Hossfeld Bender’s versatility allows for clean, professional-grade square bends, making it ideal for applications that require structural integrity and aesthetic appeal. Always refer to the manual for specific die configurations and bending techniques to achieve optimal results.

Safety Guidelines

Always wear protective gear, ensure proper die setup, and maintain a clean workspace. Avoid loose clothing and keep hands clear of moving parts during operation.

6.1 Operating Safety Precautions

Always wear safety glasses, gloves, and appropriate clothing to prevent injury. Ensure the workspace is clear of debris and well-lit. Never operate the bender near loose clothing or long hair that could get caught. Keep hands and fingers away from moving parts during operation. Properly secure the material before bending to avoid slippage. Familiarize yourself with emergency stop procedures and ensure they are easily accessible. Use the correct die sets for the material to prevent machine strain. Avoid overloading the bender beyond its capacity. Regularly inspect the equipment for wear and tear. Follow all instructions in the manual to ensure safe and efficient operation.

6.2 Emergency Procedures

In case of an emergency, immediately activate the emergency stop button to halt the machine. Disconnect the power supply and ensure the bender is completely stopped before addressing the issue. If a part malfunctions, do not attempt to repair it while the machine is operational. Inspect the equipment thoroughly and consult the manual or contact a professional if needed. In case of injury, provide first aid and seek medical attention promptly. Keep a fire extinguisher nearby and ensure proper ventilation in the workspace. Familiarize yourself with these procedures before operating the bender to ensure quick and effective responses during emergencies.

Parts and Accessories

The Hossfeld Bender includes interchangeable die sets, additional tooling options, and a comprehensive parts list for customization and repair, ensuring optimal performance and versatility in various projects.

7.1 Understanding Die Sets

Die sets are essential components of the Hossfeld Bender, enabling precise bending of various materials like tube, pipe, and flat stock. They determine the radius and angle of bends, with specific dies for round, square, or flat stock. Interchangeable designs allow customization, while optional tooling expands capabilities. Understanding die sets is crucial for achieving accurate results and maintaining equipment performance. Regular inspection and proper storage ensure longevity. The instruction manual provides detailed guidance on selecting and using die sets effectively, ensuring optimal bending outcomes for diverse projects.

7.2 Additional Tooling Options

The Hossfeld Bender offers a variety of additional tooling options to enhance its functionality. These include specialized dies for specific bending tasks, such as flat stock bending or creating square bends. Optional tooling expands the bender’s capabilities, allowing users to handle different materials and shapes effectively. The instruction manual provides detailed guidance on installing and using these tools, ensuring optimal performance. Understanding these options helps users maximize the bender’s versatility and achieve precise results in various projects. Proper use of additional tooling, as outlined in the manual, is crucial for maintaining equipment performance and achieving desired outcomes.

The Hossfeld Bender is a reliable and versatile tool, with its instruction manual providing comprehensive guidance for safe and effective operation, ensuring optimal results in metalworking projects.

8.1 Key Takeaways

The Hossfeld Bender instruction manual is an essential resource for mastering this versatile tool, offering detailed guidance on setup, operation, and maintenance. It ensures safe and effective use, covering topics like hydraulic hardware installation, bending techniques, and troubleshooting common issues. The manual also highlights the importance of routine maintenance to prolong the tool’s lifespan and performance. With clear instructions and illustrations, it empowers users to achieve precise bends for various materials, including tube, pipe, and flat stock. Additionally, the manual provides insights into advanced features and accessories, such as different die sets, enhancing the bender’s capabilities. By following the manual, users can unlock the full potential of the Hossfeld Bender for professional and DIY projects alike.